In the intricate machinery that powers our modern world, lubricants play a crucial but often overlooked role in ensuring smooth operations. These substances, typically in the form of oils or greases, reduce friction and wear between moving parts, extending the lifespan of machinery and reducing energy consumption. However, what many may not realize is that the stability of these lubricants is of paramount importance. Assessing lubricant stability is not merely a technicality; it is a critical aspect of maintaining the efficiency and longevity of industrial equipment.

Lubricant Stability Defined

Lubricant stability refers to a lubricant's ability to maintain its physical and chemical properties under various operating conditions. This includes exposure to high temperatures, pressures, contaminants, and prolonged use. Over time, lubricants can undergo changes that can negatively impact their performance. These changes can manifest as increased viscosity, oxidation, degradation, and the formation of harmful byproducts.

The Significance of Assessing Lubricant Stability

-

Equipment Reliability: In industrial settings, equipment downtime can be costly and disruptive. Lubricant instability can lead to increased friction, heat, and wear in machinery, ultimately resulting in unexpected breakdowns. Assessing lubricant stability helps predict potential issues and schedule maintenance proactively, reducing the risk of unexpected failures.

-

Energy Efficiency: Lubricants that have deteriorated can require more energy to maintain optimal performance, leading to increased energy consumption and operational costs. Regular stability assessments can help identify when it's time to change or replenish lubricants, ensuring equipment operates efficiently.

-

Environmental Impact: As industries strive to reduce their environmental footprint, lubricant stability assessments play a crucial role. Degraded lubricants can release harmful emissions and contaminants into the environment. By monitoring stability, companies can reduce the environmental impact of their operations and meet sustainability goals.

-

Longevity of Equipment: Lubricants act as a protective barrier between moving parts, reducing friction and wear. A stable lubricant helps extend the lifespan of machinery, saving companies money on replacements and repairs.

-

Quality Assurance: For manufacturers, ensuring the stability of lubricants is essential to producing high-quality products. If lubricants degrade during the manufacturing process, it can lead to defects and product failures. Quality control processes rely on assessing lubricant stability to maintain consistency.

-

Compliance with Regulations: Many industries are subject to strict regulations regarding emissions and environmental impact. Monitoring and ensuring lubricant stability can help companies comply with these regulations and avoid fines and penalties.

Assessing Lubricant Stability

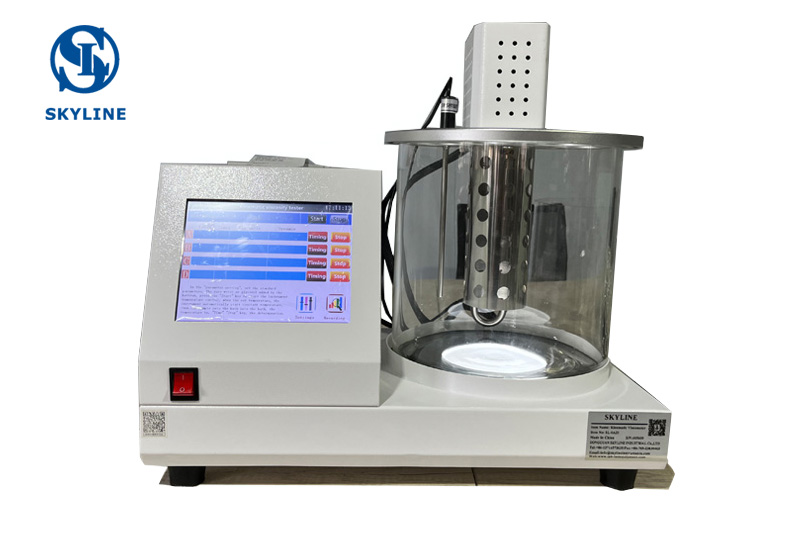

Assessing lubricant stability involves various laboratory tests and on-site monitoring techniques. Common tests include measuring viscosity, oxidative stability, acid number, and analyzing the presence of contaminants. These assessments help identify potential issues early on and guide decisions regarding lubricant replacement or replenishment.

In conclusion, assessing lubricant stability is far from a trivial matter; it is an integral part of maintaining efficient, reliable, and environmentally responsible industrial operations. With the advancements in technology and the increasing emphasis on sustainability, monitoring and managing lubricant stability have become indispensable practices for industries across the board. By doing so, companies can ensure smoother operations, reduce costs, and contribute to a more sustainable future.